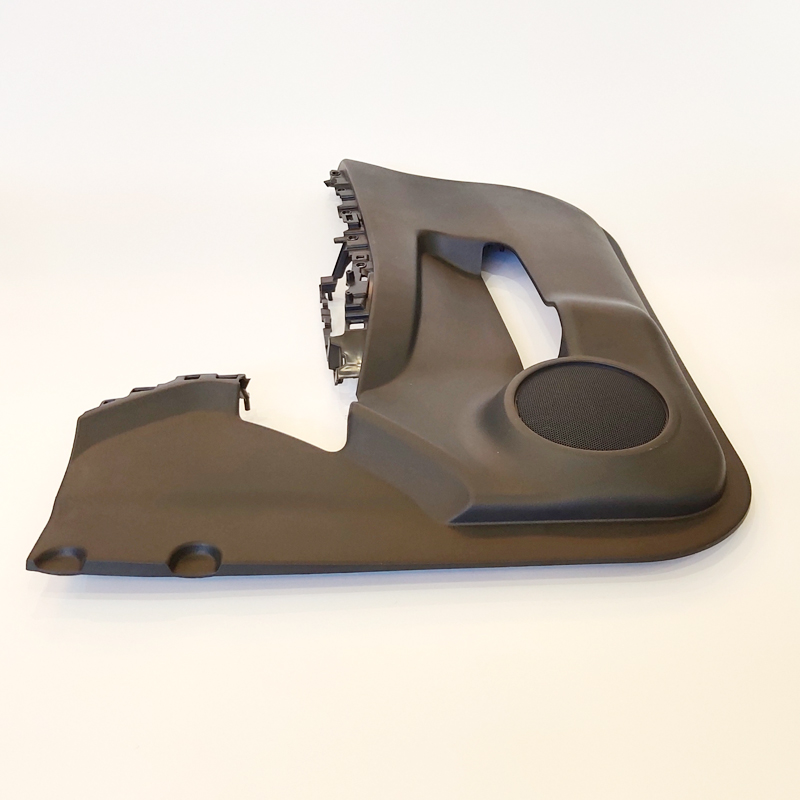

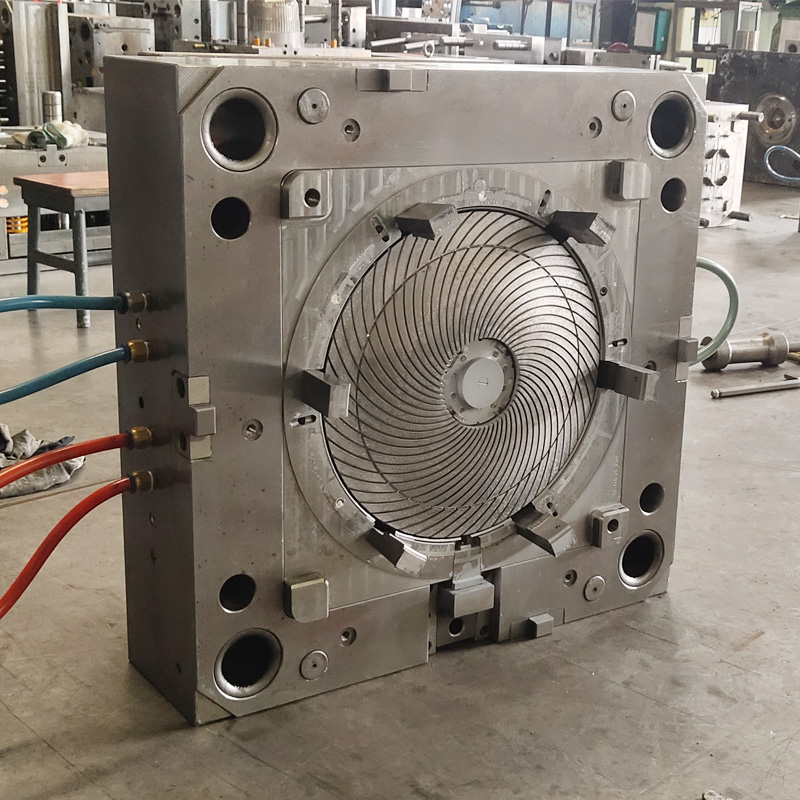

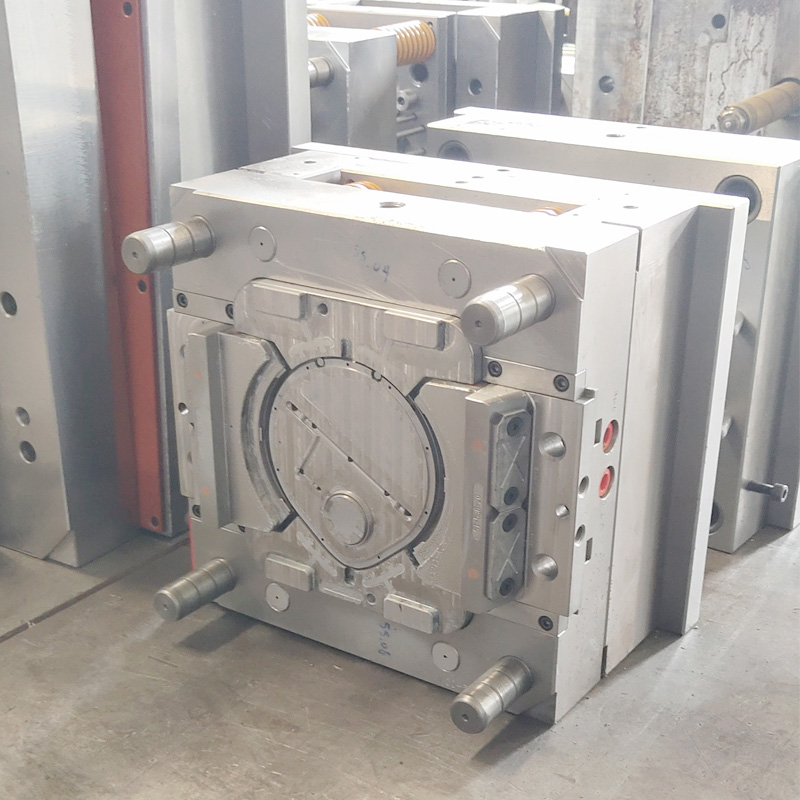

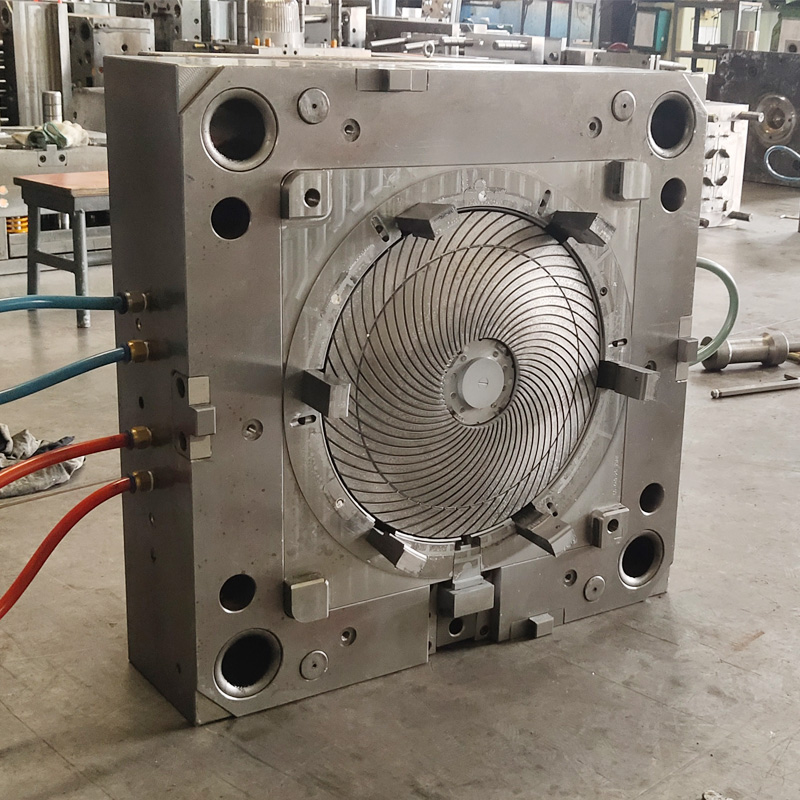

Plastic automobile parts protection cover Automotive interior connection parts auto clips and plastic fasteners plastic mold

Five Advantages Of Products

- rich experience in medical mold R&D

- Competitive Price and good service

- Quick Delivery time(2-4 weeks)

- ISO Certificated with the srtictest quality control system

- 23 Years OEM&ODM Mould-making and Plastic processing experience

Product Details

BP plastic injection mold manufacturer was founded in 2000.our company specialized in plastic injection mould design ,mold manufacture and injection molding .we achieveved ISO 4000 & TS16949 certificate. We have acquired advanced mold process and inspection equipment more than 100 sets , advanced molding machines from 80T to 2000 150units. Our mainly products including automotive components & household appliances & medical and aerospace plastic injection molds and so on , We also provide excellent engineering design services to our customers, through early engagement in design for manufacturability, design for assembly and fast prototyping to meet the time to market and time to volume customer’s needs. our client from all over the Word ,we impressed our customers with competitive price and high quality and excellent service . We, BP injection mold maker , to be your trustable and reliable partner of professional tool maker and high-end injection molding service provider. We look forward to servicing you to enable your business success by designing and delivering premium quality products through plastic injection tooling fabrication and plastic parts injection molding.

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

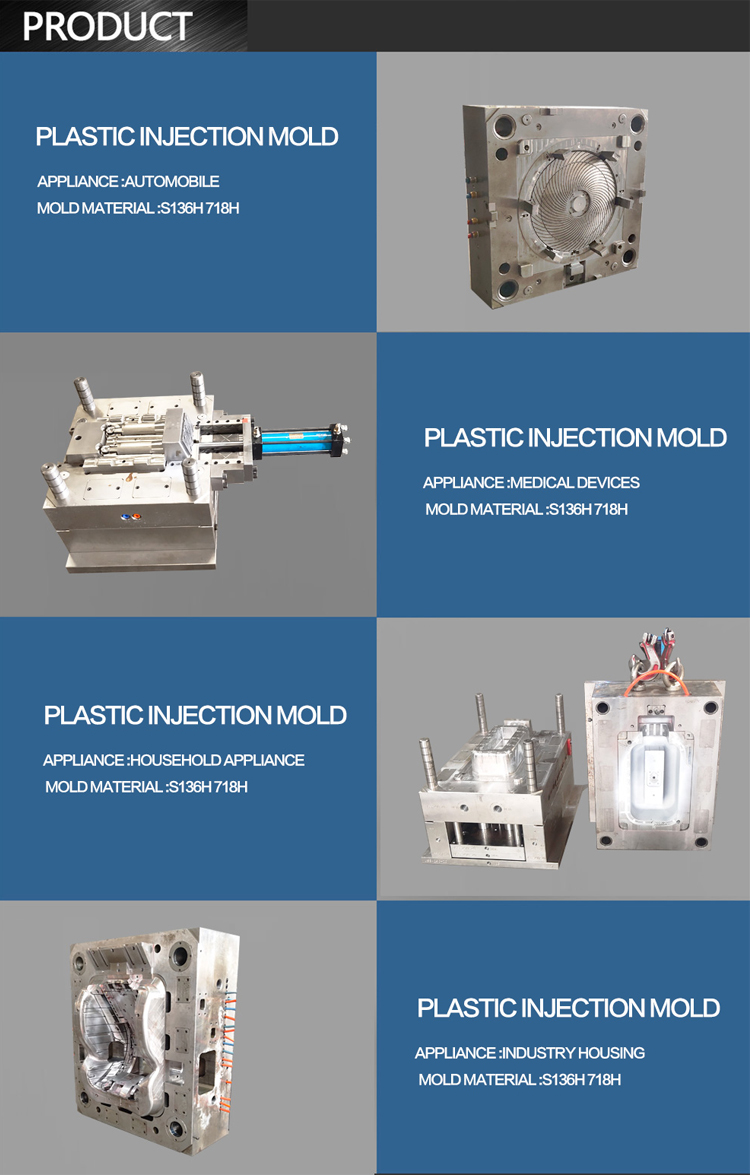

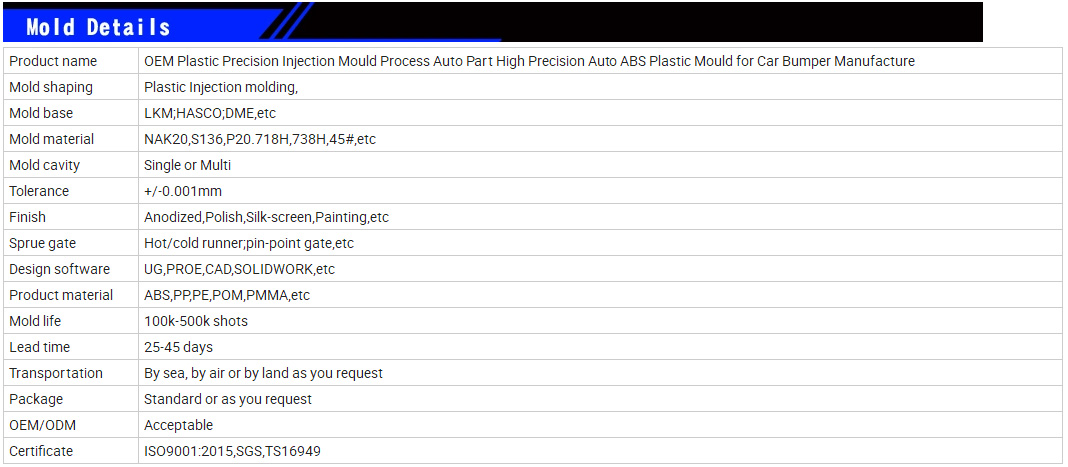

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Q: Are you a factory or trading company?

Q: Are you a factory or trading company?

A: HMT is an injection mold factory in Guangzhou of China, welcome to visit us.

Q: How can I get the quotation?

A: We will submit the quotation in 24 hours if getting detailed information during working days.In order to quote for you earlier, please provide us the following information together with your inquiry.

1) 3D Step of Files and 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels,delivery,etc.

Q: What are the main oversea markets of HMT?

A: Currently HMT regular oversea customers are from the US, the UK, Italy, Germany, France and India etc.

Q: How you do the quality control?

A:

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: What should we do if we receive defective products?

A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

A:

1).For moulds, we will be coated one-layer anti-rust oil first,and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Jiangmen Billow Peak Technology Co., Ltd.

Contact Person: Jim

Department: Sales Department

Post: Sales Manager

Telephone: +86 13430862828

Landline: +86 13430862828

Company Address: No. 11 Gaoxin East Road, High-tech Zone ,Jiangmen City,Guangdong ,China

Website: www.billowpeak.com

Previous: precision injection parts Automot...

-

Professional custom auto connector and terminal mold Man...

-

Plastic automobile parts protection cover Automotive inte...

-

precision injection parts Automotive accessories plastic...

-

Household product Plastic Injection Molds Manufacturers

-

Shock resistance Insulating Concerns Car DashPlastic Part...

-

Long time use High Polish High Polish mould Plastic Injec...

-

Professional OEM injection mould for abs/pc/pvc/pp/pa66/p...

-

silicone medical mold/reaction injection molded medical p...